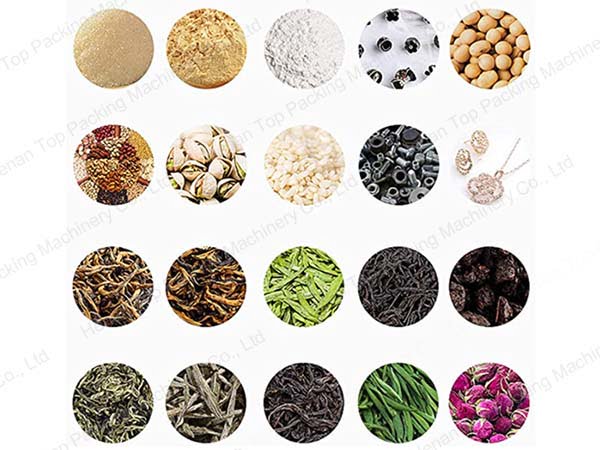

เครื่องบรรจุเชิงปริมาณ เป็นโซลูชันการบรรจุที่หลากหลายซึ่งออกแบบมาเป็นพิเศษสำหรับการวัดและบรรจุวัสดุแห้งและของแข็งอย่างแม่นยำ มีการใช้กันอย่างแพร่หลายในอุตสาหกรรมต่างๆ สำหรับการจัดการผง เม็ด และส่วนประกอบฮาร์ดแวร์ขนาดเล็ก

ด้วยประสิทธิภาพสูง ความแม่นยำ และความสามารถในการปรับตัว เครื่องจักรนี้จึงเหมาะสำหรับธุรกิจที่ต้องการปรับปรุงความสม่ำเสมอในการบรรจุภัณฑ์และผลผลิต ด้านล่างนี้คือพื้นที่การใช้งานหลักของเครื่องจักร.

1. ผลิตภัณฑ์ผง

ในอุตสาหกรรมที่มีผลิตภัณฑ์ที่เป็นผงแห้งทั่วไป เครื่องบรรจุเชิงปริมาณ ช่วยให้มั่นใจได้ถึงการบรรจุที่แม่นยำ ลดฝุ่น และปรับปรุงประสิทธิภาพการบรรจุ เหมาะสำหรับทั้งผงเกรดอาหารและผงอุตสาหกรรม

- วัสดุทั่วไปเช่น แป้ง, นมผง, ผงกาแฟ, ผงพริก, ผงโปรตีน, ผงเคมี

- ข้อดีหลัก:

- การบรรจุที่มีความแม่นยำสูงพร้อมของเสียจากวัสดุน้อยที่สุด

- ความเร็วในการเติมและน้ำหนักที่ปรับได้

- ติดตั้งฟีเจอร์ควบคุมฝุ่นเพื่อให้แน่ใจว่าความสะอาด

2. ผลิตภัณฑ์เกล็ด

สำหรับวัสดุที่เป็นเม็ด ความสม่ำเสมอของน้ำหนักการบรรจุเป็นสิ่งสำคัญ เครื่องบรรจุเชิงปริมาณ ใช้ระบบการสั่นสะเทือนหรือสว่านเพื่อควบคุมการไหลของเม็ด ทำให้ได้ผลการบรรจุที่เสถียรและทำซ้ำได้

- วัสดุทั่วไปเช่น ข้าว, ถั่ว, น้ำตาล, เมล็ด, เกลือ, เม็ดอาหารสัตว์, เม็ดพลาสติก

- ข้อดีหลัก:

- การบรรจุที่สม่ำเสมอแม้สำหรับเม็ดที่ไหลได้หรือไม่สม่ำเสมอ

- การออกแบบหัวเติมหลายหัวแบบเลือกได้เพื่อผลผลิตที่สูงขึ้น

- เข้ากันได้กับขนาดถุงและภาชนะที่หลากหลาย

3. อุปกรณ์และชิ้นส่วนขนาดเล็ก

ในอุตสาหกรรมฮาร์ดแวร์และส่วนประกอบอิเล็กทรอนิกส์ เครื่องสามารถใช้ในการนับและบรรจุรายการขนาดเล็ก เพื่อให้แน่ใจว่ามีจำนวนที่ถูกต้องต่อแพ็ค

- วัสดุทั่วไปสกรู, น็อต, แหวนรอง, โบลต์, ชิ้นส่วนพลาสติก, องค์ประกอบอิเล็กทรอนิกส์

- ข้อดีหลัก:

- การนับที่แม่นยำและการบรรจุตามน้ำหนัก

- สนับสนุนการรวมกับเซ็นเซอร์นับและสายพานลำเลียง

- ลดแรงงานคนและข้อผิดพลาดในการบรรจุ

บทสรุป

ไม่ว่าจะเป็นผงละเอียด เม็ดหยาบ หรือชิ้นส่วนเครื่องจักรขนาดเล็ก เครื่องบรรจุเชิงปริมาณ นำเสนอโซลูชันการบรรจุที่มีประสิทธิภาพ อัตโนมัติ และแม่นยำ ช่วยให้ผู้ผลิตลดต้นทุนแรงงาน ลดการสูญเสียผลิตภัณฑ์ และปรับปรุงความสม่ำเสมอของการบรรจุโดยรวม ด้วยการกำหนดค่าที่ปรับแต่งได้เพื่อให้ตรงกับประเภทผลิตภัณฑ์และความต้องการผลผลิตที่แตกต่างกัน จึงเป็นตัวเลือกที่เหมาะสำหรับอุตสาหกรรมที่หลากหลาย