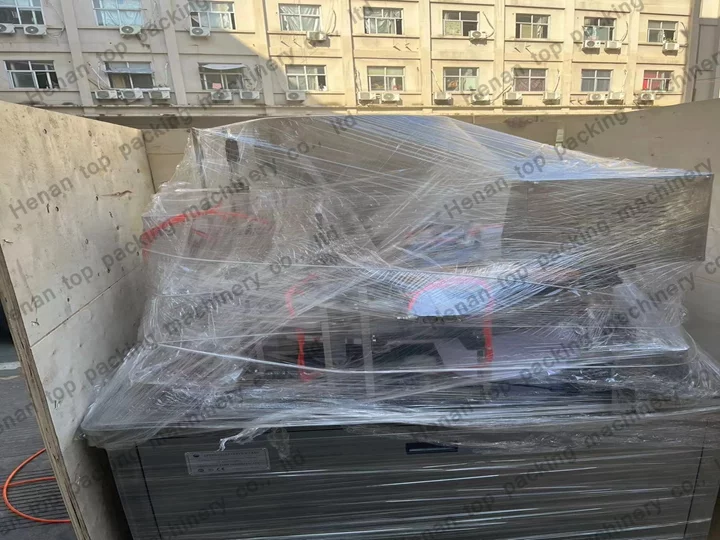

We recently sold a 요거트 충전기 to a customer in Australia. The client runs a local factory focusing on cheese and yogurt production.

이전에는 작은 수동 충전 장치를 사용했지만 생산 수요가 증가함에 따라보다 자동화되고 효율적인 기계로 업그레이드하기로 결정했습니다.

고객 요구 : 수동 제어를 유지하면서 효율성을 향상시킵니다

The yogurt cup filling machine was mainly used for adding oil to the surface of cheese products. During our discussion, the customer emphasized the need for manual control of the rotating tray for specific operation steps. To meet this requirement, we worked with our factory team and provided a tailored solution by adding a foot pedal system, allowing for flexible switching between manual and automatic operation.

맞춤형 전압 및 공기 압축기 구성

Since Australia’s voltage standard differs from ours, we offered a customized voltage option. We also provided a matching air compressor, ensuring the yogurt cup filling machine could be used directly without additional equipment. We maintained our service quality and provided all necessary technical support.

피드백 및 향후 계획

After using the machine, the customer shared positive feedback — accurate filling, smooth operation, and practical manual assistance via the foot pedal. They were very satisfied with the solution. The customer also mentioned their plan to upgrade more yogurt filling equipment in the future and is looking forward to continuing cooperation with us.