The yogurt cup filling machine is a fully automatic rotary equipment designed for filling and sealing various liquids and pastes such as yogurt, milk, juice, and sauces. The machine features a stainless steel structure that meets food hygiene standards and ensures easy cleaning and maintenance.

Equipped with a rotary steel plate and precision cup molds, the machine efficiently completes the entire process—from cup dropping and material filling to lid placing, sealing, and final product discharge. This streamlined workflow significantly improves production efficiency.

Two capacity options are available to meet different production needs: 800–900 cups per hour with a single outlet, and 1600–1800 cups per hour with a double outlet. This makes it an ideal solution for dairy producers and food processing plants seeking efficient and hygienic cup packaging.

What material can be packaged in the cup by automatic cup filler?

The automatic cup filler is suitable for a wide range of liquids and pastes, making it ideal for various food industries. Common products include:

- Dairy products: yogurt, ice cream, coffee cream.

- Desserts: jelly, chocolate sauce.

- Beverages and spreads: juice, jam, peanut butter.

- Sauces: tomato sauce, chili sauce, beef sauce.

Thanks to its high precision and stable operation, the machine handles materials of different viscosities—from smooth liquids to thick pastes—ensuring accurate filling, clean packaging, and consistent product quality. It is a versatile solution for both consumer and industrial packaging needs.

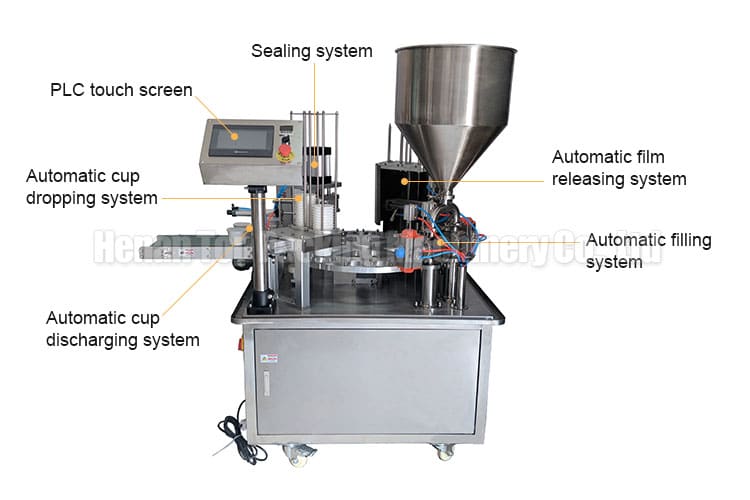

Main structure of the cup filling and sealing machine

The yogurt cup filler consists of the mold for cup placing, cup placing device, filling system, cup cover placing device, sealing system, and cup output system. The mold is customized according to the shape and size of the cup. There is a single-cup and double-cup type for choosing. And the double cups type works more efficiently. The cup falling system is driven by pneumatic power.

When the cup mold is under the cup falling device, it will fall cup into the mold for filling. The filling system adopts a piston quantitative filling system, the filling volume can be adjusted. Some common filling pumps optional include 1-10ml, 10-100ml, 5-50ml, 50-50ml, 3-30ml, 30-300ml, etc. Its sealing part is suitable for pre-made cup covers or plastic film sealing covers.

Features of the cup filling sealing machine

- Compact structure, high automation, advanced technology, simple operation.

- The body of the yogurt cup filling machine is made of stainless steel, which is stable and durable.

- Automatically feeding cup, filling, feeding cup cover, sealing, and conveying the final product.

- Heat sealing effect is beautiful and firm, uneasy to leak from the cup.

- Equipped with a sensor for detecting, it will not fill material if there is no cup under the filling nozzle.

How about the automatic cup filling sealing machine price?

The price of this rotary cup filling and sealing machine is closely related to its production speed, filling volume, and configuration. Double-cup filler can produce nearly twice the single-cup type, and the price of double-cup mold fillers is higher. The filling volume is controlled by the liquid and paste pump. The bigger the liquid paste filling pump, the price is higher.

The yogurt cup filling machine adopts well-known fittings brands. It means the equipment requires more cost. Besides, there are some other elements, such as freight, manufacturing material, supporting machines, and so on.

Technical data of yogurt cup filling machine

| Model | KIS-1800 |

| Power | 220V 1200W |

| Packaging speed | 800-900cups/h (single outlet) 1600-1800cups/h(double outlet) |

| Air pressure | 0.5-0.75Mpa |

| Maximum air consumption | 0.45m3/m |

| Dimension | 100*80*120cm |

| Weight | 350kg |

Invest in our yogurt cup filling machine

If you’re in search of a solution to enhance yogurt production efficiency, our yogurt cup filling machine stands as an ideal choice. Whether your production scale is small or large, we offer tailored solutions to meet your specific needs.

Committed to providing customization, technological innovation, quality assurance, and comprehensive service, we ensure to fulfill your requirements and achieve production goals.

By the way, we also have other types of filling machines, so feel free to reach out to us for further details and pricing inquiries. Choose us for reliability, efficiency, and quality assurance!