Automatic bottle labeling machine is the equipment that labels on the bottles and cans. There is a labeling machine for round bottles, square bottles, cone bottles, etc. And the common types of labels include three styles, a long label, a short label, and two short labels. Bottle labeling machine widely applies to the beverage, daily chemical, cosmetic, food, medicine, petrochemical, and other industries. There is a fully automatic bottle labeler and semi-automatic bottle labeler, for round, square, or cone bottles. The labeling system may be different because of the different label lengths and bottle shapes. Besides, we offer OEM service.

Automatic round bottle labeling machine

The sticker labeling machine for the round bottle adopts an infrared ray positioning device. When it detects the bottle, the three upright rollers and a down pressing device will lock the bottle to spin a circle for labeling firmly. People not only can adjust the distance between two small rollers, but also the big roller and small rollers. If the two small rollers are slanted in a trapezoid shape, they can be used to label cone bottles. The beer bottle labeler is suitable for a long label or two short labels for the circumference of the bottle. It is equipped with a set of label rollers, and two short labels are on one roll. We provide the vertical type and desktop type. The vertical type is higher, convenient to connect with other machines to compose a production line. The portable one is low, but light. Their conveyor belts both are adjustable according to the diameter of the bottle.

Main components of automatic sticker bottle labeling machine

- PLC touch screen: People can set using language, running speed of conveyor belt, the labeling time, the speed of labeling wheel, production output display, label output test, lock bottle test, and so on.

- Rolls of label conveying device: Label conveying rollers are used for making the label to the bottle labeling device smoothly.

- Labeling system: When the bottle enters the labeling part, a label will stick on the bottle. Then make the label on the bottle firmly by pressing and spinning.

- Conveyor belt: The conveyor belt is the main conveying system for bottles and cans. Its width is adjustable according to the container. And it can be lengthened and widened if the bottle is big.

- Handles: People can adjust the width of the conveyor belt, the distance and height of the labeling part by different handles.

Round bottle labler’s applications

The automatic round labeler has a wide range of applications in bottled beer, wine, tomato sauce, peanut butter, fruit jam, milk, yogurt, skin water, cosmetic, ice cream cup, cough syrup, shower gel, medicine bottles, liquid detergent, hand sanitizer, disinfectant, alcohol, pesticide, and other industries.

Technical data of automatic bottle labeling machine

| Model | PLM-200R | PLM-120R (Desktop type) |

| Applicable bottle | Round bottle | Round, cone bottle |

| Power | 110v/220v 50/60HZ 800w | 850W, 110v/220v 50/60HZ |

| Labeling speed | 20-80pcs/min | 30-60pcs/min |

| Precision | ±1mm | ±1mm |

| Label length | W≤120mm | L:20-150mm W: 20-120mm |

| Label roll outer diameter | 300mm(max) | 300mm(max) |

| Label roll inner diameter | 76mm | 76mm |

| Bottle size | Φ:25-100mm,W:10-150mm L:15-300mm | Φ: 20-80mm L:20-150mm |

| Machine size | 1800*1300*1500mm | 1200*680*600mm |

| Weight | 260kg | 85kg |

Square bottle labeling machine

Square bottle labeler is the special equipment for one side or two sides of flat bottles. Unlike the labeling machine for round bottles, the automatic flat bottle labeling machine does not need a positioning device. The label will stick on the bottle automatically one by one. Besides, for the double-side labeling type, the two labels are on different rolls, requiring the two sets of label conveying devices. These bottles will go through two side conveyor belts so as to flatten the labels on the bottles. Furthermore, the equipment can add round sponges on the two sides of the conveyor belt if needed.

The detailed parts of the flat bottle labeling machine

What products in the market are applies to the flat bottle labeler?

The flat bottle labeling machine is suitable for flat or square bottles of liquor, fruit juice, liquid soap, perfume, hair oil, cleaning water, milk, yogurt, cans, etc.

Square bottle labeler’s parameter

| Model | PLM-450D | PLM-80P (Desktop type) |

| Applicable bottle | Flat, square, or cone bottle | Flat, square bottle |

| Power | 110v/220v 50/60HZ 1.5kw | 800W |

| Labeling speed | 60-80 Pcs/min | 10-30pcs/min |

| Precision | ±1mm | ±1mm |

| Label length | W≤120mm | L:20-100mm W:20-100mm |

| Label roll outer diameter | 300mm(max) | 300mm(max) |

| Label roll inner diameter | 76mm | 76mm |

| Bottle size | Φ:20-100mm,H:10-150mm L:15-300mm | L: 20-150mm W:20-150mm |

| Machine size | 2800*1500*1600mm | 1250*650*800mm |

| Weight | 400kg | 38kg |

Manual bottle labeling machine

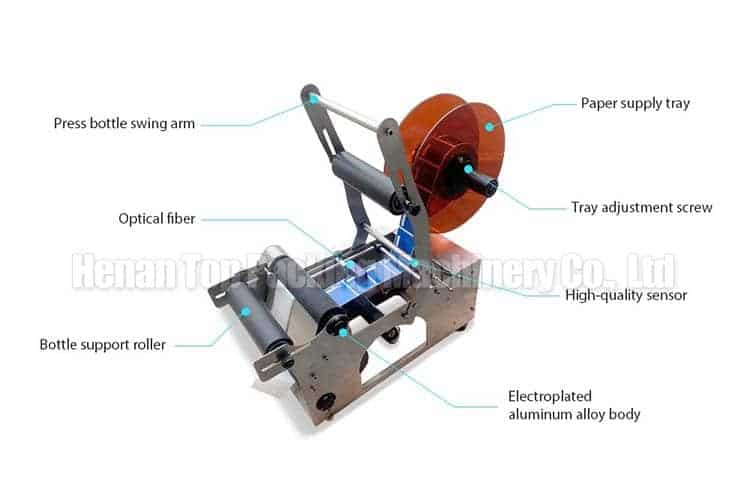

As the name implies, the semi-automatic labeler requires the operator to place the bottle on the rollers, locking the bottle to label. The machine is small and simple, suitable for small businesses or homes.

Semi-automatic bottle labeler’s structure

Detailed technical data of the semi-automatic bottle labeling machine

| Model | PLM-720D |

| Applicable bottle | Cone, round, or square bottle |

| Power | AC 110v/220v 50/60HZ 2kw |

| Labeling speed | 20-120 pcs/min |

| Precision | ±1mm |

| Label size | W:≤120mm |

| Label roll outer diameter | 300mm(max) |

| Label roll inner diameter | 76mm |

| Bottle size | H:30-300mm W:20-120mm |

| Machine size | 2800*1500*1600mm |

| Weight | 500kg |

What machines can compose a production line with the labeling machine?

The labeling process is one step of packaging. Before bottle labeling, you can match a bottle unscrambler, a bottle washing machine, a filling machine, and a capping machine. After labeling, the labeler can connect with an ink-jet printer, carton sealing machine, and so on. If you are interested in it, welcome to consult us. We have a professional team to offer the solutions.