Fruit juice extraction is an important part of the bottled juice production line. The bottled juices in the market are usually going through the extracting, filling, capping, labeling, coding, carton sealing, etc. There are various kinds of fruit juice extractors, juice bottling machines, bottle capping machines, date printers, carton sealing machines for choosing. The packaging solutions will be different for different production outputs and specific requirements. The final solution depends on the actual situation. If you are interested in it, welcome to contact us to get more details.

Fruit juice extractor machine for sale

For juice production, there are small juice press machines and large types for sale. The small ones can produce 500kg to 1500kg per hour. If the production output is large, we provide the equipment for 2T, 3T, 4T, …,16T.

Main structure of the small juice press machine

The small juice processing machine is composed of a screw squeezing device, a filter screen, and a container for fruit scraps. If the raw material is hard, such as apple, orange, carrot, pear, it’s better to be equipped with a crushing device. These materials, including tangerine, strawberry, grape, tomato, do not need crushing parts. There are various specifications of filter screens available.

How does the screw juice extractor work?

When working, the motor drives the main shaft to rotate at a constant speed through a pair of pulleys. And the material is chopped by the high-speed rotating hammer. Due to the action of centrifugal force, liquid juice will flow out through the filter screen. The screw is the main component of the screw juice extractor. The bottom diameter of the screw gradually increases along the direction of the slag outlet, so the space reduces when the materials are going to the outlet. This design makes the material are squeezing enough.

Installation, operation and maintenance of the fruit juicer

- The machine must be installed horizontally and fixed with anchor screws.

- When the equipment starts, the pressure head should be adjusted to maximize the annular gap, and then the gap will gradually decrease. Then use the brake to fix the position of the handwheel bearing seat.

- The feeding must be even, and it is strictly forbidden for other hard matter to enter the hopper to avoid damage to the screen.

- The filter should be washed with water and a brush after each shift. If the juice with more fibers is filtered, it depends on the production situation. The bearing should be replaced regularly and filled with clean grease. The normal operating temperature of the bearing is less than 75 degrees.

Fruit press machine parameter

| Model | CYP-0.5 | CY-0.5 | CYP-1.5 |

| Voltage | 380V/50Hz | 220V/380V/50Hz | 380V/50Hz |

| Processing capacity | 500kg/h | 500kg/h | 1500kg/h |

| Power | Squeezing power: 1.5KW Crushing power: 0.75KW | 2.2KW | 2.2+4KW |

| Filter screen | / | 0.6mm | 0.6mm |

| Dimension | 1100*350*1280mm | 1110*450*950mm | 1280*550*1485mm |

| Weight | 200kg | 83kg | 550kg |

Large automatic juicer

The big screw juice extractor is equipped with two screws, also named the double helix continuous fruit juice extractor. It consists of a frame, transmission system, feeding part, squeezing system, hydraulic system, protective cover, and electrical control part. The double screws include a feeding screw and a pressing screw. The press screw rotates with the main shaft, and the material conveying the screw sleeve spins inversely with the pressing screw on the main shaft. two screws have the same rotation speed and opposite directions. The materials contact parts are all high-quality acid and alkali-resistant stainless steel.

Applications of electric fruit and vegetable juicer

The large commercial fruit juicer is suitable for grape, sea-buckthorn fruit, pomegranate, garlic, pear, ginger, spinach, lotus root, and other fruits and vegetables containing more fiber, domestic garbage, vegetable market garbage, kitchen garbage, residue, and other fibrous materials de-watering.

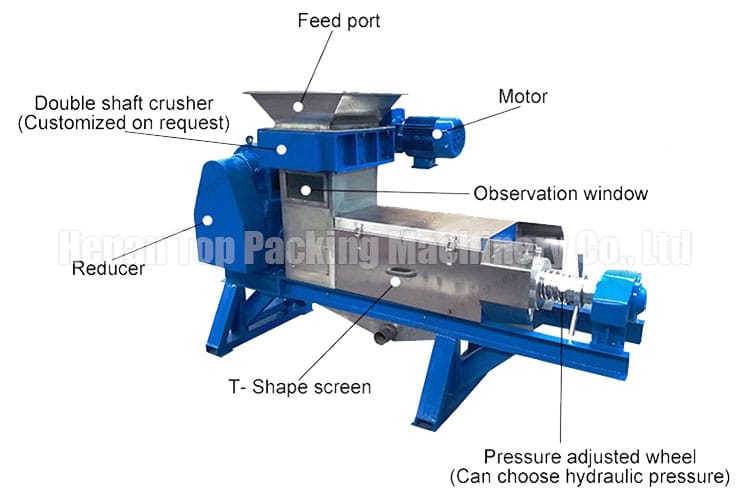

Large screw press machine’s structure

Technical data of the automatic screw juice press machine

| Model | TH-15 | TH-30 | TH-50 | TH-100 | TH-150 |

| Capacity | 0.2-1.5t/h | 0.5-2t/h | 2-6t/h | 3-10t/h | 5-16t/h |

| Diameter of conveying screw | 260mm | 350mm | 420mm | 500mm | 600mm |

| Pitch of conveying screw | 150mm | 200mm | 210mm | 280mm | 280mm |

| Diameter of the pressing screw | 260mm | 350mm | 420mm | 500mm | 600mm |

| Speed of the pressing screw | 5-15r/min | 5-15r/min | 5-15r/min | 5-15r/min | 5-15r/min |

| Power | 5.5kw | 7.5kw | 11kw | 18.5kw | 22kw |

| Screen diameter | 270mm | 360mm | 430mm | 510mm | 610mm |

| Screen aperture | 1.5mm | 1.5mm | 2*40mm | 2*40mm | 2*40mm |

| Size(m) | 2.2*0.6*0.9 | 3.5*0.7*1 | 3.5*1*1.5 | 3.8*1.1*1.65 | 4.5*1.1*1.65 |

| Weight(kg) | 650kg | 1200kg | 2550kg | 2950kg | 4200kg |

The production capacity is based on the actual material. The weight and overall dimensions of the equipment are reference data, and the actual situation shall prevail.

Juice filling machine for sale

We provide four types of liquid filling machines for juice, including linear liquid bottle filler, rotary liquid filler, rotary cup filling machine, and continuous cup filling and sealing equipment. The inline juice bottling machines can be equipped with 4. 6, 8, 10 filling nozzles. While the rotary liquid bottle filler at least has 12 spouts. For juice in cups, the rotary cup filler applies to the small production. If it’s a large output, the continuous juice cup filling sealing machine is a good choice.

Juice bottle capping machine

The juice bottle cap sealing machine is used to tighten the cap of the bottle. Before this equipment, most customers match a cap falling machine to feed caps. There is a vacuum capping machine and automatic bottle capping machine available. The former is used to cap glass bottles with iron caps. The latter is applies various plastic round caps with screw thread. It is composed of a conveyor belt, a touch screen, four frictional wheels, a side conveyor belt, bottle detector, motors, etc. The width of the conveyor belt can be adjusted according to the bottle’s size.

Bottle labeling machines for juice

As the packaging machine manufacturer and supplier, we supply the labeling equipment for round bottles, square bottles, flat bottles, cone bottles, etc. All the labeling machines adopt sticker labeling. For different shapes and sizes of the bottles, the labeling machine’s structure will be different, especially the labeling parts. We provide fully automatic and semi-automatic types.