We recently sold a yogurt filling machine to a customer in Australia. The client runs a local factory focusing on cheese and yogurt production.

Previously, they used a small manual filling unit, but as production demand increased, they decided to upgrade to a more automated and efficient machine.

Customer needs: improve efficiency while retaining manual control

The yogurt cup filling machine was mainly used for adding oil to the surface of cheese products. During our discussion, the customer emphasized the need for manual control of the rotating tray for specific operation steps. To meet this requirement, we worked with our factory team and provided a tailored solution by adding a foot pedal system, allowing for flexible switching between manual and automatic operation.

Custom voltage and air compressor configuration

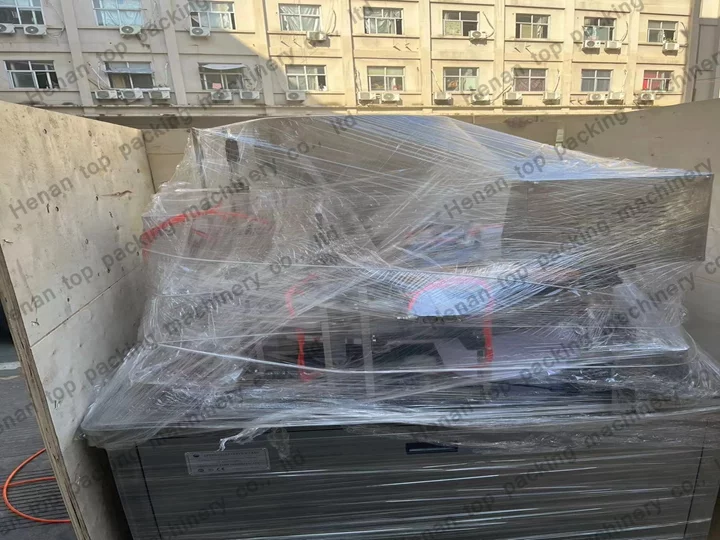

Since Australia’s voltage standard differs from ours, we offered a customized voltage option. We also provided a matching air compressor, ensuring the yogurt cup filling machine could be used directly without additional equipment. We maintained our service quality and provided all necessary technical support.

Feedback and future plans

After using the machine, the customer shared positive feedback — accurate filling, smooth operation, and practical manual assistance via the foot pedal. They were very satisfied with the solution. The customer also mentioned their plan to upgrade more yogurt filling equipment in the future and is looking forward to continuing cooperation with us.