The meat packaging machine is an essential tool for efficiently packing various types of meat, such as chicken, beef, duck, pork, and more. At Henan Top Packing Machinery Company, we specialize in two primary types of meat packaging machines: vacuum meat packaging machines and pillow packing machines. These machines are designed to ensure the meat remains clean, hygienic, and safe for consumption.

The vacuum packaging machine removes air from the packaging to extend the shelf life and maintain the freshness and nutritional value of the meat, while the pillow packing machine provides a neat and visually appealing package for individual or small portions. Packaging meat with these advanced machines not only prevents contamination and spoilage but also ensures compliance with food safety standards.

If you are in search of a reliable and efficient meat packaging machine, Henan Top Packing Machinery Company offers high-quality solutions tailored to your needs. Contact us today to discuss your requirements and find the perfect packaging solution for your business. We look forward to helping you enhance your meat packaging processes and ensure the highest standards of food safety.

Various Applications of Meat Packaging Machines

The meat packaging machine is, generally speaking, not only for packing all kinds of meat, namely food but also for packaging non-food. Such as a vacuum meat packaging machine is vacuum packaging equipment in essence, suitable for chicken meat, fish, beef, pork, duck, mutton, sauce products, spices, preserved fruits, grains, bean products, chemical products, medical products, etc.

The pillow packing machine is for meat with trays, vegetables, mooncakes, fruits, biscuits, masks, etc. The machines are automatic packaging machines, whose strengths are to release the workforce and reduce artificial touch, beneficial to the control of the sanitary environment, especially for the food industry. We are looking forward to your message!

Vacuum Packaging Machine for Meat on Sale

Meat is usually packed by the vacuum packing machine in order to extend the shelf life and prevent the microorganisms in the air. Four types are available in our enterprise, respectively single chamber vacuum packaging machine, double chamber vacuum packaging machine, stretch film vacuum sealer, and external suction vacuum sealer. Among these machines, when using a single chamber vacuum sealer and double chamber vacuum sealer, you should consider the product size due to the limited space.

The stretch film vacuum packing machine can vacuum lots of products at the same time, which vastly improves the working efficiency. When vacuuming the product with the external suction vacuum packaging machine, the product should be held manually. However, a meat vacuum packing machine has the advantages of preventing spoilage, avoiding secondary pollution, and keeping fresh and convenient to store. Want to know more about this machine? E-mail us now!

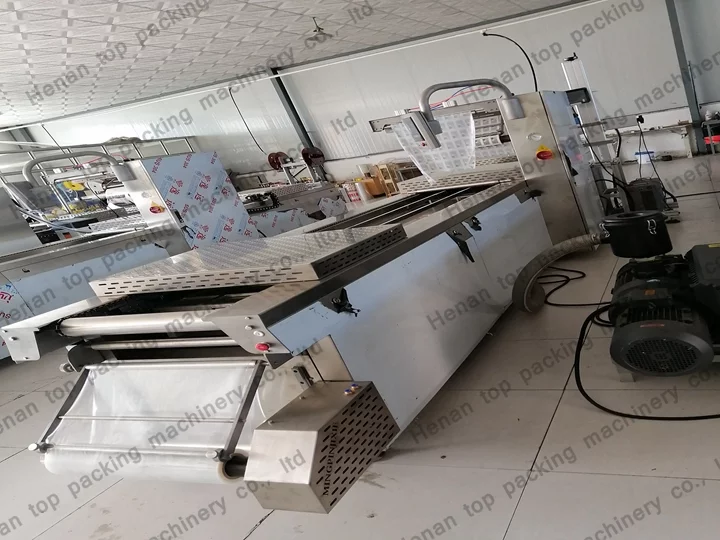

Automatic Pillow Packing Machine for Meat

In addition to vacuum packaging, automatic pillow packing machines offer another efficient solution. Here’s what you need to know about these versatile machines.

Pillow packing machine, or horizontal packaging machines, are very common in the packaging meat industry. It’s divided into two types: one is the film reel above the conveyor belt, and the other one is the film reel below the conveyor belt. The horizontal packing machine has two motors: the larger motor controls the feeding, discharging, and cutting; the smaller one is in charge of pulling and sending the film.

The Servo motor is optional. If you choose a servo motor, its conveyor belt is a leather belt with a sensor, which is able to sense the product material without wasting the film and stop by itself when there is no film. As a result, it saves time and film, no empty bag is packed, and it’s proved that the machine has stable performance. Are you interested? Come to us to boost your business!

Next, let’s explore the parameters of these meat packaging machines!

Basic Parameters of Vacuum Packing Machine

| Machine name | Single chamber vacuum packaging machine | Double chamber vacuum packaging machine |

| Voltage | 220V/50HZ | 380V/50HZ |

| Vacuum pump power | 0.9 kW | 1.5 kW |

| Sealing power | 0.6 kW | 1.17 kW |

| Absolute pressure | 0.1 pa | 0.1 pa |

| No. of sealing strips | 1 | 2 |

| Sealing strip size | 500 mm*10 mm*2 | 500 mm*10 mm*2 |

| Chamber material | 304 stainless steel | 304 stainless steel |

| Cover material | Organic glass | Organic glass |

| Chamber size | 525*520*130 mm | 525*520*130 mm |

| Machine size | 650*580*960 mm | 1260*605*960 mm |

| Machine weight | 80 kg | 150 kg |

Basic Parameters of Stretch Film Vacuum Packaging Machine

| Upper film width | 396 mm |

| Under film width | 422 mm |

| Size of the room | 400*(200~400)mm |

| Packing speed | 90-110 bags/min |

| Machine weight | 1500 kg |

| Power | 10 kW |

| Dimension | 5.8*0.9*1.9 m |

| Note | OEM service is available. |

Basic Parameters of Horizontal Packaging Machine

| Model | TH-250 | TH-350 | TH-450 | TH-600 |

| Film width | Max. 250 mm | Max. 350 mm | Max. 450 mm | Max. 600 mm |

| Bag length | 45-220 mm | 120-280 mm | 130-450 mm | 120-450 mm |

| Bag width | 30-110 mm | 50-160 mm | 50-80 mm | 50-180 mm |

| Product height | Max. 40 mm | Max. 60 mm | Max. 70 mm | Max. 70 mm |

| Packing speed | 40-330 bag/min | 40-230 bag/min | 30-180 bag/min | 30-180 bag/min |

| Power | 2.4 kW | 2.6 kW | 220V, 50/ 60HZ, 2.6KVA | 220V, 50/ 60HZ, 2.6KVA |

| Weight | 800 kg | 900 kg | 900 kg | 800 kg |

| Dimension | 3770*670*1450 mm | 4020*745*1450 mm | 4020*745*1450 mm | 3770*670*1450 mm |

Advice on Selecting Meat Packaging Machine

Several pieces of advice are here for your reference. Determine what kind of meat you are going to pack. Usually, you want to pack a few kinds of meat, but the effect of the special machine is better than the compatible machine. High-quality and valuable machines are the first primary principle. The packing equipment has a tremendous improvement to ensure stable quality and technology.

Besides, try to select the enterprise with good after-sales service. Our company has a high reputation and a powerful and professional team to provide strong technical support and timely after-sales service. Welcome to contact us today!

What is the Meat Packaging Equipment Price?

A lot of factors have a big influence on the packing machine price. For a meat packaging machine, firstly, you should know what machines you want to pack meat. Two types of alternatives are here for you. Every type differs in price. A vacuum packaging machine is to vacuum the air from the packed meat; a pillow packing machine is to wrap the meat to keep insulated from the air.

Secondly, diverse performance for the packing machines. A vacuum sealer is to be stably run and with a simple structure; a horizontal packing machine can be equipped with the servo motor and corresponding servo driving system; the better the performance is, the higher the price is. Thirdly, pay close attention to the quality. We are always keeping the principle of quality first, no matter how the cost changes. It’s very useful for you to choose the packing machine.

How to Choose Reliable Meat Packaging Machine Suppliers?

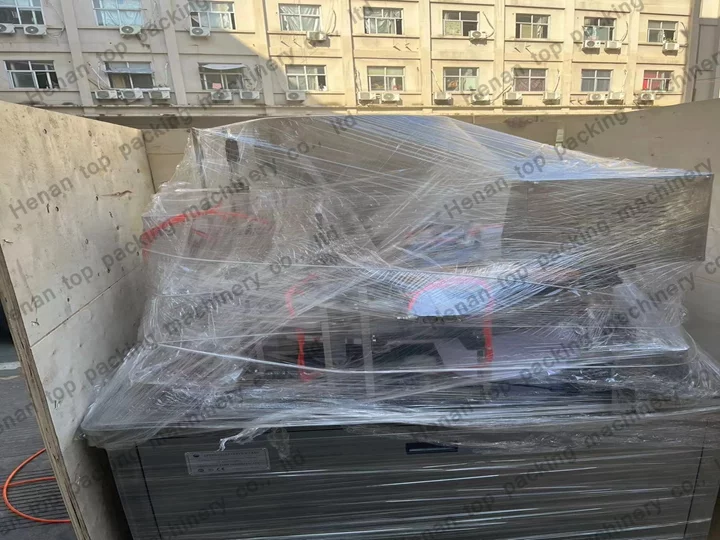

Taking us as an example, details are described below. As meat packaging machine manufacturers and suppliers, we have won many honorary titles. We have been engaged in the production of meat packaging equipment for nearly thirty years, and our machines passed CE, ISO 9001, and GMP and gained certificates.

We mainly design and make packing machines which substitute for the old fashioned ones, to boast the powerful production abilities, as well as domestically leading and world-advanced technology. Also, we are manufacturing the machines, and all the packing devices we produce are of excellent quality. As the producer and provider at the same time, you can get the best quality and valuable packing machine from us. We highly appreciate your reply!

Good Maintenance for Meat Packaging Machine

Every kind of packing machine needs to do maintenance, including meat packing machines. Before starting the operation, check carefully each part of the packing machine, and commissioning, if anything, do the correct thing in time, and keep the machine in perfect condition. Because it’s meat packing equipment, cleaning is necessary after finishing the work.

Rinsing the machine is to achieve the goal of keeping the machine hygienic, which is also giving more confidence to use your products. Regularly do maintenance and make a good record. You cannot wait for the time when do maintenance to maintain. You’re supposed to do it before the machines need to be maintained. And don’t forget to make records, which is clearly for you to get to know the machines. If you are in this business and want to get more information, leave your message!

Leave your messages!

Our meat packaging machines combine advanced technology and high-quality materials to provide efficient and reliable solutions for businesses of all sizes. Whether you operate a small farm or a large meat processing facility, our equipment meets your needs, ensuring your products stay fresh, safe, and hygienic.

By choosing our machines, you not only get exceptional performance but also benefit from our professional after-sales service and technical support. Contact us today to learn more and get a quote. Make your meat packaging process more efficient and convenient!