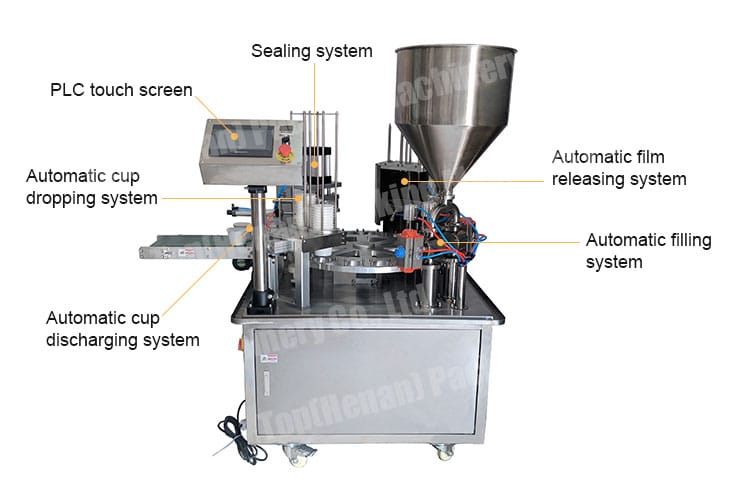

The yogurt cup filler machine, as an advanced packaging equipment, consists of multiple precision components designed to optimize the packaging process and enhance production efficiency.

Let’s delve into the structure and functionalities of these machines to gain a comprehensive understanding of their internal workings.

Automatic Touch Screen Control System

At the core of the yogurt cup filling machine lies the automatic touchscreen interface, serving as the control center for the entire packaging operation. Through an intuitive control interface, operators can effortlessly manage key functions such as cup dropping, filling, film placement, sealing, and product counting.

This advanced technology not only enhances efficiency but also ensures precision and consistency in every step of the process.

Cup Dropping System

The cup dropping system, driven by pneumatic force, embodies reliability and precision. Its seamless operation facilitates the smooth transfer of cups to subsequent stages, laying the foundation for a seamless packaging process.

Gearing and Pulling System

The gearing and pulling system comprises a robust drive motor, speed reducer, and stable gearing device. This system plays a pivotal role in conveying cups to the filling station, ensuring a steady and uninterrupted flow of production.

Filling System

Within the filling system, innovative designs include options for both single and double-head filling mechanisms. While both configurations excel in functionality, the double-head design stands out for its enhanced efficiency, allowing for quicker throughput and increased productivity.

Cup Cover Placing System

The cup cover placing system ensures accurate alignment and placement of seals. Once sealed, cups are seamlessly transferred to the output conveyor belt, ready for distribution or further processing.

In summary, the yogurt cup filling machine embodies a harmonious synergy of technology and engineering, meticulously crafted to meet the demanding requirements of modern packaging operations.

From its intuitive touchscreen interface to its pneumatic-driven cup-dropping system and efficient filling mechanisms, every component plays a vital role in ensuring optimal performance and quality output. With its blend of innovation, reliability, and precision, the yogurt cup filling machine stands as a testament to the relentless pursuit of excellence in packaging technology.