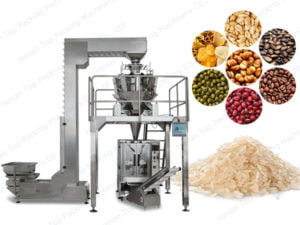

Trending Products

Various types of excellent packing machine for food and non-food products. Small vertical filling sealing machine, super-efficiency multihead weigher packing machine, flow wrapping machine, vacuum packing machine, and water bottle filling line available. Besides, we support strong packing machine OEM/ODM services.

Who We Are

Henan Top Packing Machinery Co., Ltd, was established in 1993, located in Zhengzhou City, the capital of Henan Province, China. With the almost thirty-year development, we have introduced a group of prominent professional experts to design and study in the packing machine industry. We always adhere to the principle of “customer first, quality first”, take “machines go globally, Chinese machines can make a better world” as our mission, improve the value for customers, provide growth for employees.

Partners

Contact Now

Do you have a plan to start your business? Are you interested in our packing equipment? If YES, leave your requirements below, and we will reply to you as soon as possible. Besides, we are recruiting agents and distributors around the world. Join us and begin your successful journey.