Oil packing machine is essential equipment for packaging various oils into pouches and bottles, such as coconut oil, mustard oil, edible oil, cooking oil, engine oil, etc. This machine has the advantages of a compact structure, beautiful appearance, and convenient operation. Besides, oil pouch packing machine and oil bottle filling machine are available in our company.

Being a trustworthy and honest enterprise, we also supply customization services. No matter what requirements you have, we can offer a good packing solution instead of perfunctory. So, if you’re interested in the packing machines, leave your message and we’ll be very glad to reply soon!

Excellent Oil Packing Machine for Sale

Generally speaking, the oil packing machine has two classifications: oil pouch packing machine and oil bottle filling machine. Firstly, let’s introduce oil pouch packaging equipment. It has two kinds: vertical liquid packing machine as well as lapel liquid packaging equipment. Both are automatic packing machines.

And then let’s move to the oil bottle-filling machine. It usually works with the other machines. The entire packaging process includes unscrambling, filling, capping, and labeling, but the filling is only one part of the entire packaging process. Hence, we’ll recommend the appropriate oil packing machine on the basis of your demands. Contact us as soon as possible!

Our oil packing machine offers exceptional performance and quality. Next, we will introduce the different types of automatic oil pouch packaging machines.

Types of Automatic Oil Pouch Packaging Machine

In our company, two types of optional are vertical liquid packaging machines and lapel liquid packing equipment. Undoubtedly, they’re one of the pouch packaging machines. The first one is a very simple vertical packing equipment for oil, easy structure, and simple operation.

The second one is a combined packing machine, respectively the lapel machine and the pump. Its maximum packing weight reaches 2 kilograms. In addition, the lapel machine has 420-model, 520-model, and 720-model alternatives. The pump is a measurement of liquid volume. Also, the pump is responsible for feeding. Want to know more details? Don’t hesitate to contact us very soon, and the new chapter of your business will get started.

There are various types of automatic oil pouch packaging machines available to meet different packaging needs. Let’s now take a look at the parameters of the TH-420 liquid packing machine.

Parameters of TH-420 Liquid Packing Machine

| Packing speed | 5-30 bag/min | Air consumption | 0.65 mpa |

| Bag length | 80-300 mm | Gas consumption | 0.3 m³/min |

| Bag width | 50-200 mm | Dimension | 1320 mm×950 mm×1360 mm |

| Power | 2.2 kW | Weight | 540 kg |

| Voltage | 220 V | Measuring range | 5-1000 ml |

Understanding the parameters of the TH-420 liquid packing machine will give you a better insight into its functionality and performance. Now, let’s explore the applications of the oil packing machine.

Applications of Oil Packing Machine

The oil packaging machine is definitely used for packing various oils, for example, coconut oil, mustard oil, edible oil, cooking oil, engine oil, peanut oil, soybean oil, canola oil, sesame oil, essential oil, lubricant oil, etc. It’s a liquid packing machine without a doubt. So, it’s not only for oil, but also for water, milk, soy milk, vinegar, soy sauce, wine, juice, beer, and other liquid.

Different functional machines have different allocations, which is why the price differs. What’s most important, we support the customized machine you wish. Moreover, we also supply meat packing machine, food packing machine, vegetable packing machine, candy packing machine, and other packing machines. Are you looking for this sort of machine? Get in touch with us and we’ll reply very soon!

Oil packing machines have a wide range of applications across different industries. To better understand its operation, let’s introduce the semi-automatic single-head filling machine.

Semi-automatic Single Head Filling Machine

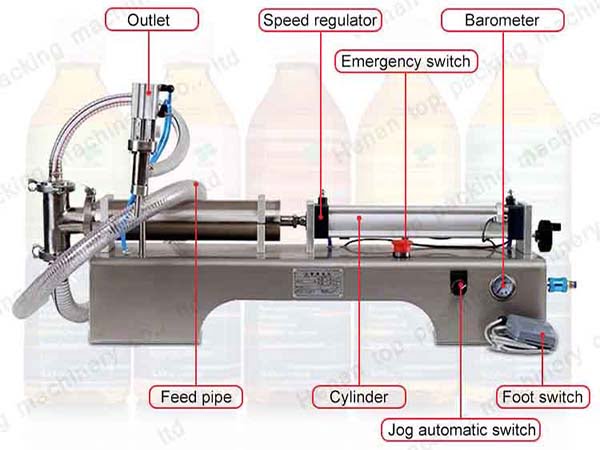

The oil bottle packaging machine plays a crucial role in filling oil into bottles, making the filling machine essential throughout the entire packaging process. A single-head filling machine, also known as a one-nozzle filling machine, performs this important task efficiently.

As a ranking top packing machine company, we, of course, have produced this machine. Its structure is composed of a footswitch, barometer, jog automatic switch, emergency switch, cylinder, speed regulator, feed pipe, and outlet. It’s very small, and suitable for investors who have low budgets.

Also, a production line covers unscrambler, filling machine, capping machine, and labeling machine. As a result, you can consider other machines for completing the production procedure when choosing a filling machine.

The semi-automatic single-head filling machine is an essential device in the oil packaging process. Next, we will compare the single-head filling machine with multiple nozzles filling machines.

Single Head Filling Machine VS Multiple Nozzles Filling Machine

The biggest difference between a single-head filling machine and a multiple-nozzles filling machine is the outlet. As the name suggests, only one outlet is for a single nozzle-filling machine. Multiple outlets, however, are for multiple nozzles filling machines, at least 2 outlets. You can get the proper collocation based on your actual needs.

Apart from this, the single nozzle filling machine is very small, placed horizontally in space. But the multi-head filling machine is much bigger and needs more space to place. Nevertheless, they’re semi-automatic machines and only one part of the whole packing process. They both belong to filling machines, no packaging function. Therefore, they should cooperate with other machines. Welcome to call us for further information.

What Advantages of Oil Packing Machine?

- The machine is made of stainless steel, a durable material, easy to clean.

- Reasonable design, simple operation, easy to understand.

- Stable performance, low noise, cost-efficiency.

- Runs stably, has more friendly user operation, long service life.

- Automatic oil pouch packaging equipment adopts a PLC touch screen, and microcomputer chips to control, automatically completing weighing, bag forming, filling, sealing, and cutting.

- Semi-automatic filling machines should cooperate with the unscrambler, capping machine, and labeling machine, so as to complete the whole production line.

- The oil packing machine is able to fill oil into pouches or bottles in accordance with your desire.

- Customization service is available.

Contact us!

In conclusion, our oil packing machines are designed to offer superior efficiency, reliability, and versatility across various applications. With advanced features and robust construction, our machines are an excellent investment for any business looking to optimize their packaging processes.

Don’t miss the opportunity to enhance your production line with our state-of-the-art equipment. Contact us today for a detailed quote and discover how our oil packing machines can meet your specific needs and boost your business performance.