Liquid filling machine is one of the packing machines, ideal equipment for good fluid liquid filling. It’s usually applied to various liquids, such as water, milk, juice, beverages, etc. This machine is of reasonable design, stable performance, as well as high filling accuracy. Besides, this filling machine is improved on the basis of advanced technology.

We also support customization services. You can inform your specific requirements and we’ll give the perfect packing solutions to you as soon as possible. We still provide the granule packing machine, powder packing machine, pillow packing machine, etc. Hence, if you have any doubts, please contact us and we’ll reply very soon!

Types of Liquid Filling Machines for Sale

Being a trustworthy and highly reputed company, we have been operating for almost thirty years. Now, in Henan Top Packing Machine Co., Ltd, single-head filling machines and multi-head filling machines are available for sale. So, it’s clearly seen that the liquid filling machine is classified according to the nozzles. Generally speaking, the filling range is 3-30ml, 30-300ml, 300-3000ml, 10-100ml, 100-1000ml, 50-500ml, 500-5000ml, 1000-5000ml.

Single-head Liquid Filling Equipment

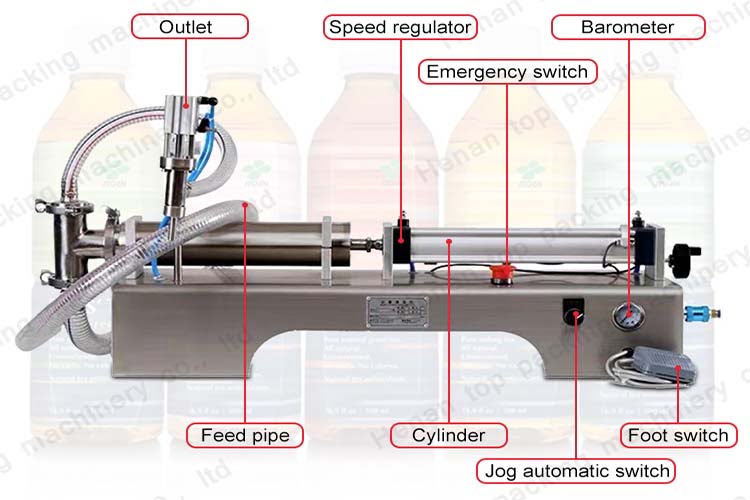

This is a very simple and horizontal single nozzle filling machine. It’s also in the name of a quantitative filling machine. It’s made of a feed pipe, cylinder, outlet, speed regulator, and barometer. The outlet is composed of stainless steel, accurate filing without clogging, and removable for cleaning and maintenance. Also, it has an emergency switch in order to stop emergencies happen. In addition, it has been controlled by the pneumatic device.

Therefore, it has to cooperate with the air compressor. Still, the liquid filling machine nozzle can be adjusted in accordance with the actual demands. The container to hold liquid varies based on your desires. It can be bottles, cans, bags, and others, whatever you like. But you should hold the container manually.

Parameters of Single-nozzle Horizontal Filling Machine

| Filling accuracy | ≤±0.5% |

| Filling speed | 1-25 bottles/min |

| Power supply | 220V50Hz |

| Required air pressure | 0.4-0.9MPa |

| Required air volume | ≥0.1m3/min( pneumatic machine, prepare on your own) |

| Working method | The air compressor is used with 220v voltage |

Multi-head Liquid Bottle Filling Machine

Multi-head filling machine can achieve the goal of filling automatically. Of course, the filling nozzles are different along with the requirements of the production. Generally, it works during the entire production line. The line consists of an unscrambler, a filling machine, a capping machine, and a labeling machine. Without a doubt, it forms a fully automatic packing machine.

What’s more, it’s equipped with a servo motor to realize an accurate and reliable filling process. An electric height adjustment system enables to adjustment of bottle height automatically. Its container is commonly bottled.

Parameters of Multi-head Filling Machine

| Voltage | AC220V 50-60Hz |

| Power | 400W |

| Production speed | 1000-1200 bottles/h |

| Air pressure | 0.6-0.8mpa |

| Filling accuracy | ±1% |

| Conveyor length | 2m |

| Required air compressor | ≥7.5Kw 200L |

| Machine size | 2000x1050x1950mm |

Features of Liquid Filling Machine

- Reasonable design, easy to operate, filling high precision.

- Contact parts adopt 304 stainless steel materials, resistant to corrosion, rust, acid, and alkali. Easy and safe to operate and maintain.

- Compact structure, beautiful appearance, with stable and reliable performance.

- Adaptability, simple operation, and easy maintenance.

- Well-knowed components so that the machine is of good quality.

- The single-nozzle filling machine has the advantages of safe and reliable work, long service life, simple maintenance, easy operation and use, high efficiency, superior performance, light structure, and wide application.

- Multi-head filling machine adopts piston quantitative, mechanical and electrical, pneumatic in one, using a servo motor to achieve no dripping during the filling.

- Customization service is supported.

What are the Applications of Filling Machines?

It’s suitable for low-viscosity fluid and liquid filling. For example water, milk, vinegar, edible oil, fruit juice, engine oil, milk tea, beverages, shampoo, hand wash, shower gel, honey, eye drops, all kinds of oral liquid, reagents, etc. You have options to select the most suitable filling machine. However, every type of selection has to satisfy your business. Of course, if you have any doubts, directly message us.

As a liquid filling machine manufacturer and supplier, we have the rich experience to answer all your inquiries. Don’t forget the customization service offered by us. Because of the customization service, we’re able to supply the machine with what you need. If anything, please contact us soon!