Multi head filling machine is designed for various granules and powders filling. It’s only the filling machine, but it can be semi-automatic or full automatic. It depends on the packing system. If only using this machine to carry on the work, it’s necessary to get help from workers. Under this circumstance, it’s semi-automatic multi-head filler. If using the packing machine such as the lapel machine to do the packaging work, in that way, it’s full automatic. Besides, we can customize numbers of the multi head, that is the feeding hopper, based on your demands. Get in touch with us for more information!

Features of Multi Head Filling Machine

- Simple design, reasonable structure and cost-effective;

- Different products can be put together to weigh different grams;

- Applicable to various materials, suitable for granular, powdery products;

- Blanking can be set on the screen at the same time;

- Stainless steel housing, durable, long service life;

- Fast dispensing speed and equivalent accuracy;

- The same product can be set to take turns through this multi head filling machine;

- Support customization, voltage can be changed.

Design Structure of Multi Head Filler

As mentioned above, this multi head filler can be collocated with the packing system, like the lapel machine. So, after collocating, it’s totally full automatic filling machine for the granules and powders. Now let me introduce this multi head filler. Its structure consists of the hopper, weight control panel, bag material, shaper, temperature control panel, protective shell.

Hopper: it’s mainly for holding materials, like granules and powders.

Weight control panel: set parameters and this weight is an electronic scale, weighing accurately.

Bag material: there are three options: OPP/CPP inflatable, aluminized, PE-aluminized-PET. Choose what you need.

Shaper: it’s bag former, making the film into the bag shape in order to fill the materials.

Multi Head Filler VS Multi Head Weigher Packing Machine

These two machines have similarities and differences.

Similarities

- Customization. Both have multi heads, customizing numbers of the weighing heads to meet requirements.

- Applicable materials. Both can be used for the granules, and the weighing range is very large.

- Weighing. Both adopt the electric scale, more accuracy.

Differences

- Automatic degree. The multi head filling equipment can be semi-automatic or full automatic, relying on the packing system. But the multi head weigher packing machine is full automatic, once completing the weighing, bag forming, filling, sealing and cutting.

- Application. The multi head filler can be used for the granules and powders, while the multi-head scale packaging equipment is only for granules.

- Machine property. Naturally, the multi head filling machine is filling equipment, but the mulit-head packing machine is packaging machine.

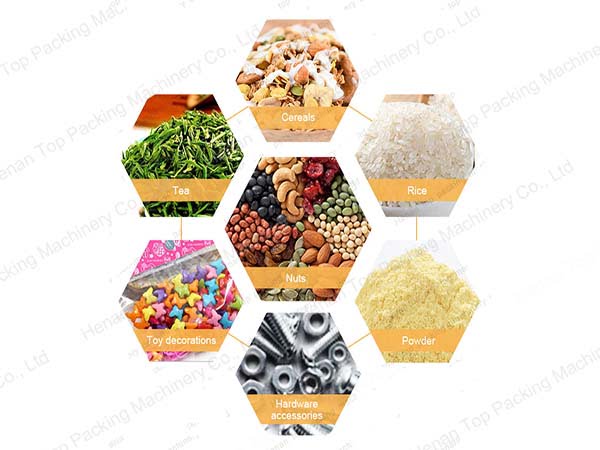

Various Applications of Multi Head Filling Equipment

This machine can be automatically weighed, suitable for a variety of materials. For example, rice, millet, whole grains, vegetable seeds, fertilizer, tea, wolfberry, dog food, fish, dried fruit, nuts, herbs, salt, spices, chestnut, sugar, washing powder, electronic, hardware, trinkets, plastic, and other small pieces. The multi head filling machine is very easy to operate, achieving the quantitative filling. Moreover, in Top(Henan) Packing Machine, we supply the small filling machine, with the same simple structure, affordable. We also provide the liquid filling machine, powder filling machine, paste filler, yogurt cup filler, etc. If you have any doubts, please contact us immediately!