The Chilli Powder Packing Machine is an automatic powder packaging solution for chilli powder, spices, seasoning powders, flour, and other fine powders. The machine adopts a PLC control system and stainless-steel structure, with adjustable packing ranges such as 0–80 g, 100–500 g, and up to 1 kg, packing speeds of 20–80 bags/min, and flexible bag lengths from 30–300 mm. It supports multiple bag styles including back seal, 3-side seal, and 4-side seal.

Widely used in food processing plants and spice production lines, this machine integrates screw auger dosing, automatic forming, sealing, and cutting in one unit. With accurate weighing, stable operation, easy adjustment, and low maintenance, the chilli powder packing machine effectively improves packaging efficiency, reduces labor costs, and ensures consistent packaging quality.

Excellent Types of Chilli Powder Packing Equipment for Sale

Generally speaking, chilli powder packing machine, to put it in another way, powder packing machine, has a semi-automatic and fully automatic packaging machine. In fact, semi-automatic packing equipment is a filling machine. When material discharges, humans should assist. While full automatic packing machine is divided into four types.

First of all, the packing machine is pushed horizontally. Secondly, it’s pushed obliquely. Thirdly, it’s pushed directly to the bottom. The last one is a combination of the lapel machine and feeding system. All in all, several types are here for you to choose from. Thus, if you’re interested in the chilli powder packing equipment, please get in touch with us as soon as possible!

Chilli Powder Packing Equipment Pushed Obliquely

This kind of packing machine has the distinguishing feature of an oblique hopper. And its range is 0-80 grams. Two handles are around the hopper. One handle is the backside of the machine, functioning to adjust the hopper’s obliquity. Another one is the side of the machine, affecting the height of the hopper. Also, there is a visible window at the backside of the machine. Through it, you can see inside clearly.

Two motors are equipped in the machine. The smaller motor is in charge of the film reel, and the bigger one is for others. Besides, its structure in proper sequence is film reel, PLC control screen, hopper, bag former, sealing, and cutting devices. You can also choose the inflatable device for nitrogen protection. Definitely, the date printer has ribbon date printing and inkjet date printing. Trust us, we can offer the perfect packing solution to you as much as we can.

Structure of powder packing machine

Packing method of powder packing machine

Parameters of 0-80g Powder Packing Machine

| Model | TZ -320 |

| Packing weight | 0-80 g |

| Packing style/bag style | 3-side seal /back seal / 4-side seal |

| Packing speed | 20-80 bags/min |

| Bag length | 30-180 mm adjust |

| Bag width | 20-150 mm (replace bag former) |

| Dimension | 650*1050*1950 mm |

| Weight | 250 kg |

| Power consumption | 1.8 kW |

| Material | 304 stainless steel |

| Note | Customization service is available |

Chilli Powder Packing Machine Pushed Horizontally

The packing machine is of the trapezoidal hopper. The discharging part is horizontal, hence the name comes. Two models are 320-model and 450-model. A big difference is the packing range. 320-model is for 0-200 g while 450-model is for 0-1 kg. It consists of a PLC control screen, hopper, bag former, and sealing and cutting devices.

PLC touch screen can set packaging speed, language, chain bag, photoelectric eye, and counting. In principle, one bag former matches with one packing machine. However, customization service is available. We can produce a customized packaging machine to meet your demands. Thus, if you’re looking for this packing machine, contact us immediately.

Parameters of 0-1kg Chilli Powder Packing Machine

| Model | 450 |

| Packing weight | 0-1 kg |

| Packing style/bag style | 3-side seal /back seal / 4-side seal |

| Packing speed | 30-75 bags/min |

| Bag length | 30-300 mm |

| Bag width | 30-215 mm |

| Dimension | 820*1250*1900 mm |

| Weight | 250 kg |

| Power consumption | 1.2 kW |

| Material | stainless steel |

| Note | Customization service is available |

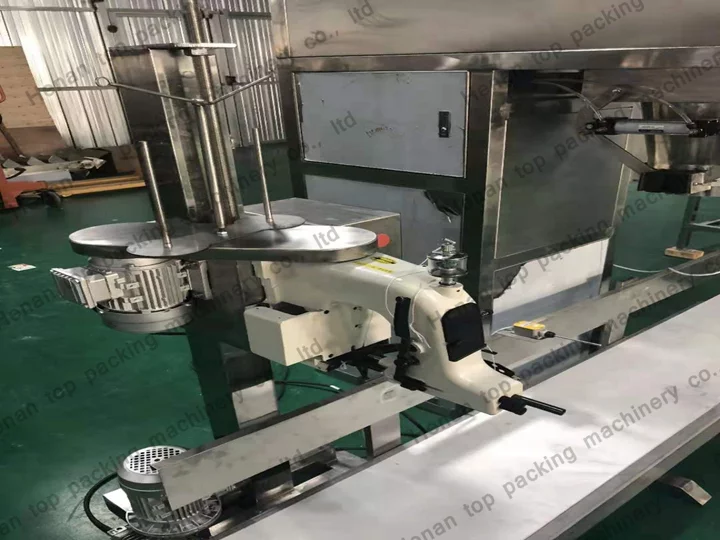

Automatic Lapel Powder Packaging Machine

The machine is a combination of a lapel machine and a feeding system of powder. The lapel machine is only a packing machine for bag making, sealing, and cutting. The name comes resulting from the lapel style. Two belts appear with the film pulling wheels after the lapel style. Moreover, the lapel machine has 420-model, 520-model, and 720-model.

Various bag styles are optional, such as gusseted bags, pillow bags with slots, etc. The pattern (strip, plain weave, overlapping curve) of the sealing area can be selected, in spite of the default back-seal strip pattern. Because it’s much firmer. The collocation is a feeding system of powder. What’s more important, there is a screw auger inside. Therefore, want to know more? Leave your message and we’ll reply very soon!

Parameters of 1-3kg Lapel Chilli Powder Packing Machine

| Packing speed | 5-50 bag/min |

| Bag length | 80-400 mm |

| Bag width | 80-250 mm |

| Air consumption | 0.65 Mpa |

| Gas consumption | 0.4 m³/min |

| Max width of roll film | 520 mm |

| Power voltage | AC220V / 50 HZ |

| Deadweight of machine | 600 kg |

| Dimension of outer packing | 1150*1795*1650 mm |

| Measuring range | 3000 ml (max.) |

| Note | Customization service is available |

What are the Applications of the Chilli Powder Packaging Machine?

In fact, chilli powder packing machine is a kind of powder packaging equipment, suitable for packaging all kinds of powder regardless of whether the powder is of good fluidity or poor fluidity. For example, chilli powder, seasoning powder, coffee powder, flour, milk powder, masala, cornflour, tapioca flour, detergent powder, and other powder.

Since the rapid process of society, chilli powder has been widely used daily. Especially regions and countries in the tropical areas. The machine has a stainless steel body and a photoelectric eye. That’s why the machine has high accuracy, and strong reliability, not easy to wear. It also fits tropical areas because of its stainless steel body.

Interested in this? Come to us for more details in time!

What’s Great Design?

The most prominent design of powder packing equipment coming from us is equipped with a screw auger. In modern industry, it’s often used horizontally or at a slight incline as an efficient way to move materials. In other words, it’s a screw conveyor. Its material is stainless steel, with wear resistance, high-temperature resistance, and corrosion resistance.

They usually consist of a trough or tube containing either a spiral blade. The spiral blade is coiled around a shaft, driven at one end, and held at the other. The rate of volume transfer is proportional to the rotation rate of the shaft. Furthermore, the screw can be customized based on your needs.

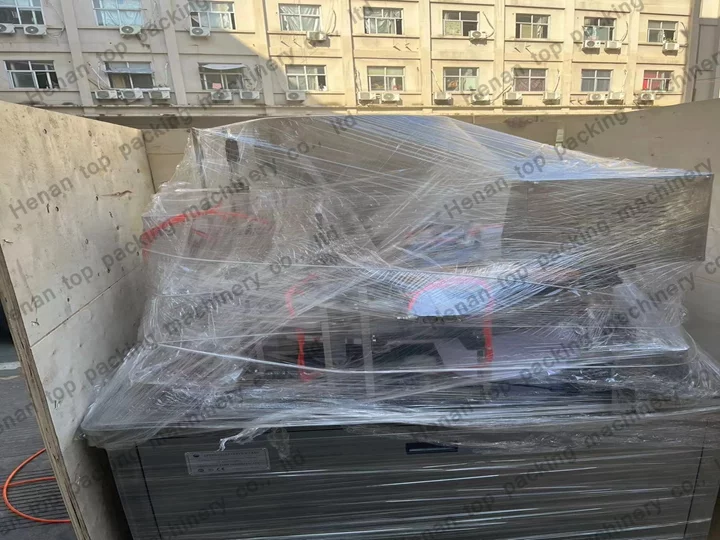

Ready for Your Business

Being a highly reputed manufacturer and supplier, our brand is formed through long-term trade and business. We have our own design and study team to follow the tendency of markets. Consequently, the chilli powder packing machine differs in various collocations.

Certainly, we still supply vegetable packing machine, candy packing machine, juice packing machine, chips packing machine, biscuit packing machine, as well as other packing machines. Looking forward to your inquiries and welcome to visit us any time!