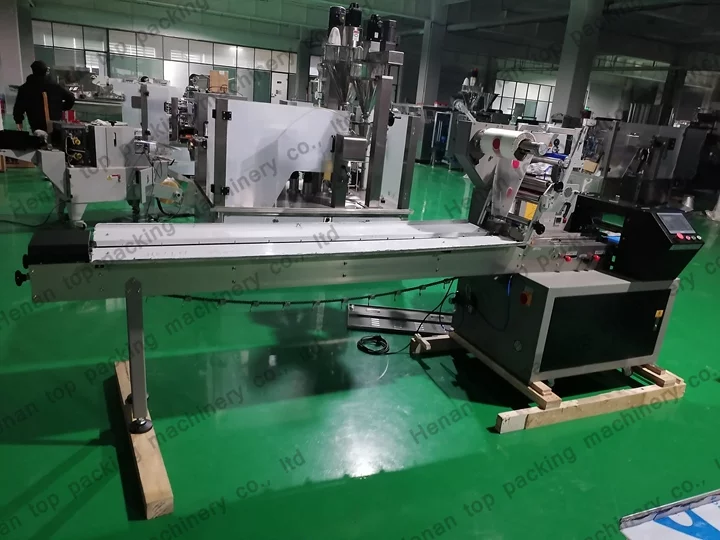

最近,我们成功向佐治亚州的一位客户交付了一台 350型号流线包装机(枕式包装机) 。这台机器主要用于食品的自动包装,帮助客户显著提高包装效率,降低人工成本,并增强产品外观的一致性。

客户背景及采购需求

佐治亚州的客户是一家本地食品加工和分销公司,向超市和零售渠道供应单独包装的食品产品。他们计划投资一台 稳定、经济的流线包装机,用于连续包装操作。

购买前的关键问题

在购买之前,客户关心以下问题:

1. 多种包装材料和兼容性

客户的产品包括 饼干、烘焙食品和其他规则形状的零食,需要机器处理多种 膜宽和袋长。

2. 稳定性和包装速度的担忧

他们担心在中高速下,机器可能出现 封口不牢、切割不准或运行不稳定,影响成品质量。

3. 预算限制

客户希望一台既能保证包装质量,又 经济实惠、维护简便,而不是投资于配置过高的高端型号的机器。

4. 操作简便和培训

由于他们之前没有使用全自动流线包装机的经验,他们更倾向于选择一台 操作和调节都简单易行的机器,以缩短员工培训时间。

我们的解决方案

为满足客户的需求和关切,我们提供了以下专业解决方案:

推荐型号:350型号流线包装机

根据客户的产品尺寸和生产量,我们推荐了 350型号流线包装机,它在包装范围、速度和成本之间取得了平衡,非常适合中小型食品工厂。

详细参数和演示

我们为客户提供了 详细的技术规格、包装演示和工作流程图,清楚展示了机器对不同产品尺寸的适应性,并建立了对其性能的信心。

优化配置以实现稳定运行

机器具有 稳定的传动结构和精确的切割系统,确保 整齐的封口、准确的切割和顺畅的运行,即使在连续高速生产中,也能减少包装损失。

用户友好的操作

350型号流线包装机配备了 直观的控制面板,操作员可以轻松调整参数。即使是没有经验的员工,也能经过简单培训后操作机器。

机器型号及技术参数

- 机器名称: 流水线包装机(枕式包装机)

- 型号: 350

- 最大膜宽: 350 毫米

- 包装速度: 40–230包/分钟(根据产品尺寸可调)

- 袋长调节: 自动

- 适用薄膜: BOPP、OPP、OPP/CPP、复合膜等

- 电源: 220V / 50Hz

- 产品高度范围: ≤ 40–60 毫米

- 适用行业: 食品、日用品及其他常规或半常规形状的产品

客户包装材料及应用

客户主要使用流线包装机包装:

- 饼干、曲奇和其他烘焙产品

- 单独包装的零食

- 规则形状的食品

部署后,机器生产的包装具有 外观均匀、封口牢固,显著提高整体生产效率,满足本地市场对 干净、吸引人的小包装的需求。

客户反馈

安装和运行后,客户对350型号流线包装机的 稳定性、包装速度和操作简便性给予了积极反馈。他们表示,机器完全满足了他们的期望,并为未来的生产扩展奠定了坚实的基础。

总结

成功出口的 350型号流线包装机 到佐治亚州,解决了客户在包装效率和人工成本方面的痛点。